In industrial processes, flow dividers play a crucial role in ensuring accurate and efficient fluid distribution across multiple channels. Choosing the right flow divider can significantly impact operational efficiency, product quality, and equipment longevity. Unfortunately, many industries make avoidable mistakes when selecting these components, leading to performance issues, unnecessary downtime, and higher operational costs. This article explores the most common mistakes to avoid when selecting flow dividers for industrial applications, offering insights for engineers, maintenance teams, and decision-makers.

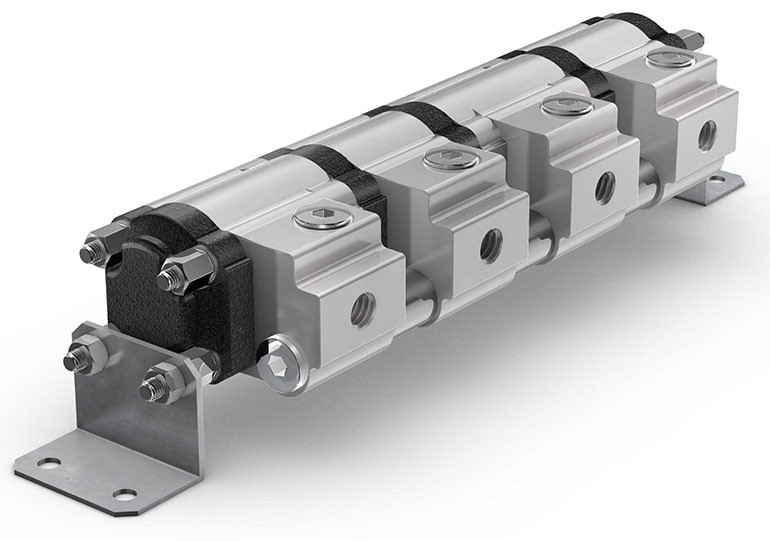

Understanding Flow Dividers and Their Importance

Flow dividers are devices used to split a single fluid stream into two or more equal or proportionate streams. They are widely used in hydraulic systems, food processing lines, and manufacturing processes that demand precise fluid distribution. In addition to distributing fluid evenly, flow dividers ensure synchronized operation of multiple actuators or machines, minimizing energy waste and maintaining system balance.

In industries like confectionery production, for example, flow dividers work in tandem with chocolate transfer pumps to ensure that liquid chocolate is evenly distributed across molds or processing lines. When the flow divider is poorly selected or improperly configured, inconsistencies in flow can cause defects, slow production, and increase wastage.

Understanding the operational requirements, flow rate, and system characteristics is critical before selecting a flow divider. Skipping this step is one of the first mistakes engineers often make.

Mistake 1: Ignoring Flow Rate Requirements

One of the most common errors is choosing a flow divider without considering the required flow rate. Each flow divider is designed to handle a specific range of flow rates. Exceeding these limits can lead to uneven fluid distribution, excessive pressure drop, and premature wear of internal components.

For applications involving chocolate transfer pumps, flow rate precision is critical. Even minor deviations can result in inconsistent filling or coating, affecting both product quality and yield. It is essential to calculate the maximum and minimum flow requirements and select a flow divider capable of operating efficiently within those parameters.

Mistake 2: Overlooking Pressure Constraints

Flow dividers are designed to function within certain pressure ranges. Ignoring system pressure requirements can lead to leakage, cavitation, or total system failure. High-pressure environments can stress the internal components of a flow divider, while low-pressure applications may fail to activate the divider mechanism properly.

In industrial applications such as hydraulics or food production, pressure stability is crucial. Chocolate transfer pumps, for instance, require steady pressure to maintain consistent flow. Selecting a flow divider without factoring in pressure constraints can disrupt the entire process, causing downtime and additional maintenance costs.

Mistake 3: Choosing the Wrong Type of Flow Divider

Not all flow dividers are created equal. They can be categorized as proportional or non-proportional, fixed or adjustable, and mechanical or hydraulic. Selecting the wrong type for the application is a mistake that can compromise system performance.

Proportional flow dividers split fluid according to predetermined ratios, making them ideal for processes that require precise distribution. Non-proportional dividers, on the other hand, simply split the flow equally. Mechanical dividers may offer simplicity and reliability, but they may not handle complex hydraulic requirements.

Understanding the system’s operational needs and matching them with the correct flow divider type is essential. For example, in food production systems using chocolate transfer pumps, proportional flow dividers may be necessary to ensure that different lines receive precisely the right amount of liquid chocolate.

Mistake 4: Ignoring Fluid Compatibility

The fluid being handled is an important factor when selecting a flow divider. Some dividers are suitable only for certain types of fluids, while others can handle a broad range of viscosities and temperatures. Using a flow divider incompatible with the fluid can result in erosion, corrosion, or contamination, all of which reduce efficiency and equipment life.

In the case of chocolate transfer pumps, the fluid is viscous and temperature-sensitive. Selecting a flow divider without considering these properties can cause blockages or uneven flow. Ensuring that the divider materials are compatible with the fluid type is crucial to maintaining process integrity and product quality.

Mistake 5: Neglecting Maintenance and Serviceability

Industrial equipment requires routine maintenance to remain operational. Flow dividers are no exception. A common mistake is selecting a model without considering ease of maintenance, access to replacement parts, or cleaning requirements.

In environments where hygiene is essential, such as food processing lines, easy disassembly and cleaning are critical. Flow dividers that are difficult to service can increase downtime and operational costs. For systems using chocolate transfer pumps, ensuring that the flow divider can be easily cleaned and maintained prevents contamination and maintains consistent product quality.

Mistake 6: Overlooking Environmental and Operational Conditions

Flow dividers are often installed in demanding industrial environments. Exposure to extreme temperatures, dust, moisture, or vibrations can affect performance. Failing to consider these operational conditions can result in premature wear or failure.

For example, in a plant using chocolate transfer pumps, the ambient temperature and humidity may vary throughout the facility. Choosing a flow divider without evaluating its ability to handle these conditions can lead to malfunction or uneven flow. Engineers should assess the operational environment carefully and select a flow divider designed to withstand these conditions.

Mistake 7: Underestimating System Complexity

Industrial systems are often more complex than they appear. Assuming that any standard flow divider will suffice is a risky mistake. Systems may have multiple branches, variable flow demands, or synchronization requirements that a simple divider cannot handle.

Working closely with system designers and thoroughly analyzing the hydraulic or processing system ensures the selected flow divider meets all operational needs. In systems involving chocolate transfer pumps, precise coordination of flow across multiple lines is essential to avoid production bottlenecks and maintain consistency.

Mistake 8: Neglecting Manufacturer Support and Documentation

Choosing a flow divider without considering manufacturer support and technical documentation is another common oversight. Reliable technical guidance, installation instructions, and troubleshooting information can save time and prevent costly mistakes.

Selecting a flow divider with robust manufacturer support ensures that any issues during installation or operation can be resolved quickly. For industries relying on chocolate transfer pumps, rapid access to support and detailed documentation minimizes downtime and maintains consistent production output.

Best Practices for Selecting Flow Dividers

To avoid the mistakes mentioned above, it is important to adopt a systematic approach when selecting flow dividers:

- Conduct a detailed assessment of system requirements, including flow rate, pressure, and fluid properties

- Identify the correct type of flow divider based on proportionality, adjustability, and compatibility

- Consider environmental conditions and operational stresses that may affect performance

- Evaluate maintenance, cleaning, and serviceability needs

- Review manufacturer support, documentation, and availability of replacement parts

- Test or simulate flow conditions whenever possible to validate the selection

Following these best practices ensures that flow dividers function efficiently, maintain consistent fluid distribution, and reduce the risk of downtime or quality issues.

Selecting the right flow dividers for industrial applications is a decision that can significantly impact operational efficiency, product quality, and maintenance costs. Avoiding common mistakes such as ignoring flow rate requirements, neglecting fluid compatibility, overlooking maintenance needs, and underestimating system complexity is essential for optimal performance.

In industries relying on chocolate transfer pumps, precise fluid management is critical to achieving consistent results. By carefully assessing system requirements, considering environmental conditions, and selecting the appropriate flow divider type, industrial operators can maximize efficiency, reduce waste, and maintain high standards of quality.

Investing time and effort in the proper selection of flow dividers pays off through smoother operations, fewer errors, and long-term cost savings. Understanding the potential pitfalls and implementing best practices ensures that fluid distribution systems operate reliably, supporting overall productivity and performance.